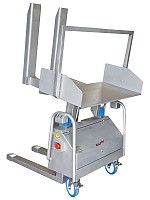

The tipper

The van Oirschot Roestvrijstaal Backsaver standard is ideal for speeding up unloading products from various types of bins like square bins, crates or even dough bowls and other containers. One of the great benefits of this very compact and mobile tipper is that it "ergonomizes" the work of your employees and reduces the risk of back strain injury to the operative! The tipper is used like an un-driven pallet truck to manoeuvre the bin, or crate (with meat, fish, vegetables or whatsoever), into position as required, e.g. at individual workstations. It is then tipped to the angle at which it is easiest for the operator to remove the contents. As the bin becomes empty it can be tipped progressively further, up to 100º(*) maximum, avoiding the need to bend over. The tipper can be used anywhere in the factory, being completely self-contained with its own power pack. The powerful battery allows a full shift (like 25 tons of meat) to be worked before recharging overnights. The machine was designed specifically for the food industry. (*) A special adapted backsaver can even tip up to 110º!! (Though castor wheels need to be build out at least 150mm due to stability issues.)

Data based on standard machine build:

Standard tipping height Approx. 970mm

Maximum tipping angle 100 degrees (stepless 0-100)

Maxumum bin weight 800kgs

Machine measures 1400 x 960mm (Length x Width)

Power supply 12V (Battery and charger included)

Used materials Completely stainless steel and food-save plastics

Machine weight Approx 320 kg.

Metryczka | Ogólne warunki handlowe | Koszty transportu | FAQ